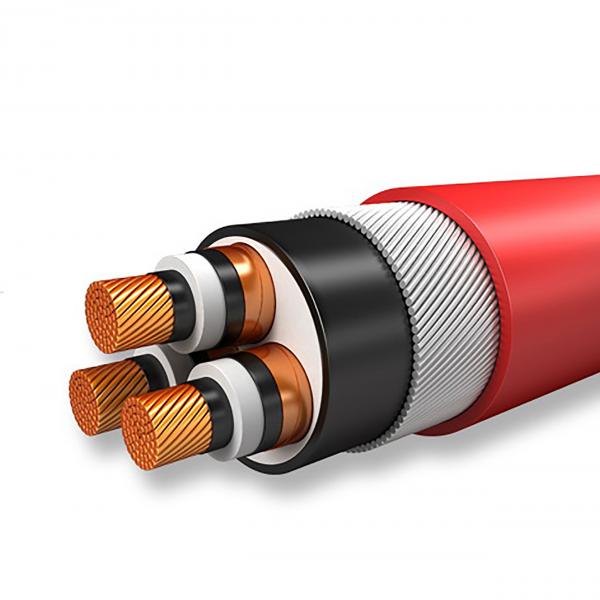

High productivity ZARLNK™ XLPE insulation enables increased productivity at low cost, whilst sustainably improving production flexibility. Keeping up with the needs of power distributors is a huge challenge for medium voltage (MV) cable makers as they need to be able to raise production levels in a cost-effective way without compromising cable quality or long-term reliability, whilst continuing to meet sustainability requirements.

With ZARLNK ™ high productivity XLPE from Borealis, cable makers now hold the key to increasing their production, whilst lowering their costs. Our ZARLNK ™ copolymer offering allows 10–20% faster cable manufacturing than classic homopolymer XLPE, whilst delivering an outstanding wet ageing electrical performance that meets the most stringent of market requirements. In addition to this, our ZARLNK ™ homopolymer offering based on Supercure technology means cable makers can potentially extend production runs by more than 30%, thanks to its superb scorch-retardant properties.

The global demand for medium voltage cables is growing. Legacy grids in developed countries need to be modernized and expanded to cope with the growing production of renewable energy and the implementation of ‘smart grids’, while emerging countries want to establish an effective infrastructure with broad reach.

Long-term performance

Regardless of the application or purpose, reducing the total Cost of Ownership through improved long-term reliability and performance is the main priority for all operators. ZARLNK ™ XLPE insulation allows for the production of medium voltage cables with a service life that may extend beyond 40 years. Moreover, our Water Tree Retardant (WTR) ZARLNK ™ (copolymers or additives) deliver outstanding wet ageing performance and meet the most stringent market requirements.

Production flexibility

Our ZARLNK ™ insulation system provides cable manufacturers the flexibility to meet the varying needs of different regions. The superb low scorch performance of ZARLNK ™ XLPE compounds allow for higher line speeds, longer running times and a lower cost per kilometer of cable, among other production

Benefits

- 10%-20% higher productivity vs standard homopolymer XLPE

- Up to 30% longer production runs

- Outstanding electrical performance

- Shorter and more flexible production cycles